1 - Inspector checks...

Inspector checks if the material is the same block and bundles numbers approved by the client.

2 - Decides on the classification,...

Decides on the classification, if he agrees or not with the classification done by the factory.

3 - Open the bundles...

Open the bundles to see the slabs inside the bundle or makes the inspection slab by slabs

5 - Checking flatness

Checking flatness, that is making sure slab is not warped.

6 - Checking polishing...

Checking polishing quality, finish of the slabs, if the corners and edges are well polished

7 - Checking for structural problems...

Checking for structural problems, such as fissures, pit holes, blade marks, wire marks, polishing marks.

8 - Taking pictures...

Taking pictures, full slab and close view of the slabs

10 - Complete the inspection report...

Complete the inspection report, all information about the bundles are in the report.

11 - Get the factory manager...

Get the factory manager or the sales person’s signature on the report. It assures they are in accordance with the inspection. A copy of the report is to the factory so they have a record for future reference if a claim is placed. Some companies don’t allow inspection slab by slab, in this case the report shows which slab was inspected, if the problem is inside the bundle they have to take care of it.

12 - Sending reports...

Sending reports. This part is done at our office, when our office name on all pictures, request packing list and commercial invoice. If necessary we request correction. After all is correct an email with Inspection report, pictures and documents are sent to the client, requesting booking.

STEP BY STEP OF YOUR BLOCK INSPECTION

1 - Two Inspectors go to the quarry carrying...

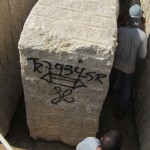

Two Inspectors go to the quarry carrying the notes and details of quality and color required by the client.

2 - All blocks are washed,...

All blocks are washed with water and the inspector makes a general inspection to see how the lot selected for inspection are overall.

3 - Inspector inspects all 5 faces...

Inspector inspects all 5 faces of the block, wet and decides the classification with the quarry manager or the sales people, or rejects the block.

4 - If the block is approved...

If the block is approved, any defects, broken corners, fissures, drill holes, are noted in the BLOCK REPORT DIAGRAM, as well as the classification.

5 - The inspectors make the measurements...

The inspectors make the measurements and note GROSS and NET measurements on the block report. If no agreement is reached with the quarry manager, the block is rejected.

6 - Once approved, the inspector paints...

Once approved, the inspector paints the clients mark on the block face, close to the suppliers block number.

7 - Block pictures are taken...

Block pictures are taken, showing defect if there are any, and showing the block number and inspector painted mark.

8 - After all blocks are inspected...

After all blocks are inspected, a list with block number, block classification and net measures are made. The list is signed in 2 copies, both signed by the quarry and inspectors.